S3030 is a pre-programmed SMT furnace front and back SMT automatic optical inspection equipment, it is equipped with multi angle RGBW light source, 4-channel small angle 3D projection system, high-resolution high-speed camera and telecentric lens, and standard Y-axis gantry dual motor drive. The equipment adopts "2D+3D fusion inspection", which obtains three-dimensional data of components and solder joints through 3D imaging, and combines 2D planar information to achieve all-round inspection, especially suitable for high-density and miniaturized components. It can achieve 3D online automatic optical inspection, which can detect defects such as missing parts, offset, reverse, floating height, side standing, monument standing, poor solder joints, solder beads, oxidation pollution, foreign objects, scratches, etc. on SMT circuit boards.

| 型号 | S3030 | |

|---|---|---|

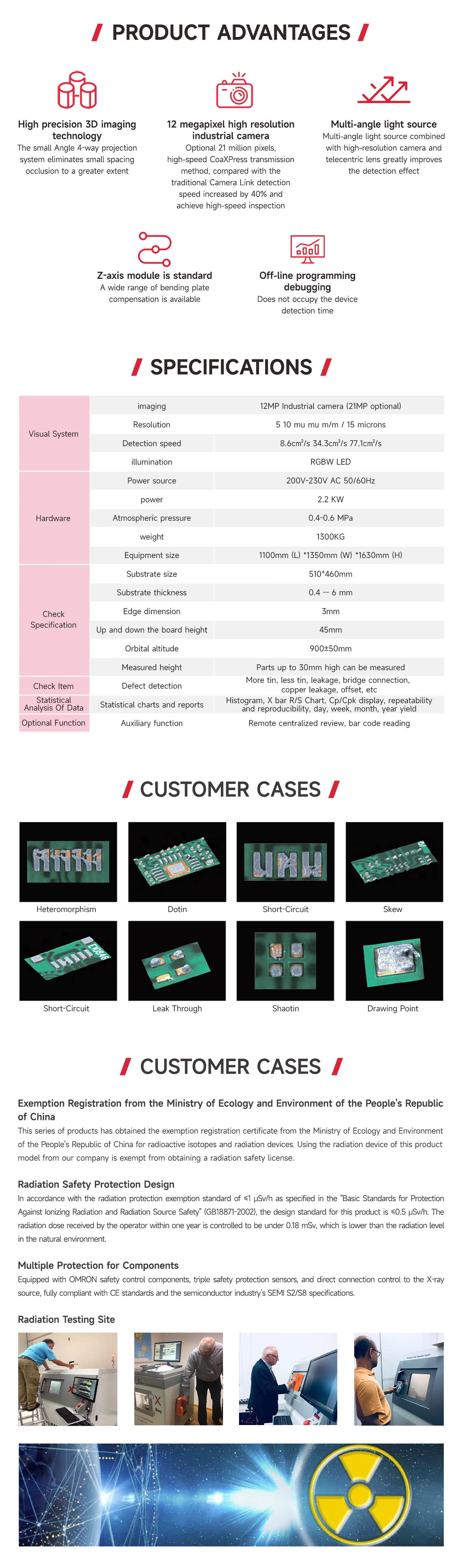

| Visual System | Imaging | 12MP industrial ca mera (2lMP optional) |

| Resolution | 5μm/10μm/15μm | |

| Inspection Speed | 6.7c㎡/s 26.7c㎡/s 60c㎡/s | |

| Lighting | RGBW LED | |

| Hardware | Power supply | 200V-230V AC 50/60Hz |

| Power | 2.2KW | |

| Air Pressure | 0.4-0.6MPa | |

| Weight | 1300KG | |

| Equipment Dimensions | 1100mm(L)*1350mm(W)*1630mm(H) | |

| Inspection Specificalions | Su bstrate Sizes | 510*460mm |

| Substrate Thickness | 0.4-6mm | |

| PCB Edge Clearancy | 3mm | |

| Top and Bottom Board Clearancy | 45mm | |

| Transport Height | 900±50mm | |

| Measurement Height | Maxium measurement height up to 30mm | |

| Optional Features | ArtificalIntelligent Inspection | Detectable defect types: Pre-oven tin balls, gold surface scartches, gold surface contamination, tin adhesion, tin balls, foreign objects |

| Auxiliary Functions | Remote centralized review, barcode reading, QCR recongnition | |

| Inspec tion ltems | Delects Inspection | Missing components, offset, overturn, billboard, tombstoning, poor soldering joint, solder balls, oxidation pollution, foreign material, scracthes, etc. |