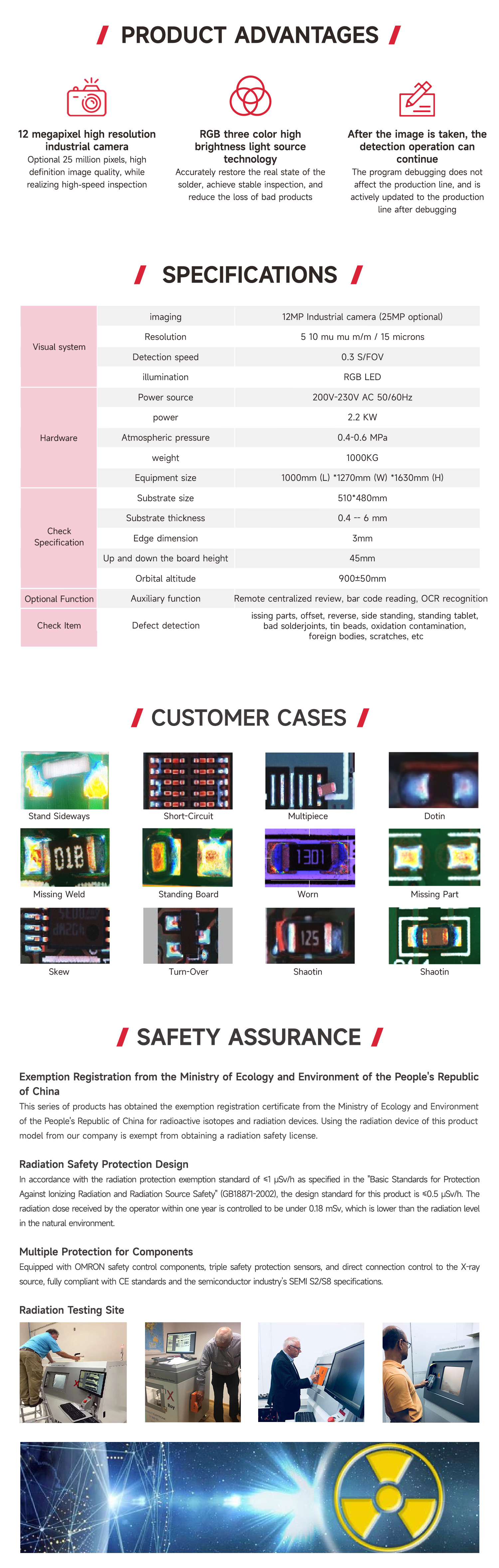

The equipment mainly uses pre-programmed automatic optical inspection of the SMT furnace front and back surface mount status. It is equipped with multi angle RGB light sources, high-resolution industrial cameras and telecentric lenses, high-definition imaging quality, and high-speed inspection. S3020 2D online automatic optical inspection equipment can inspect defects in SMT circuit boards, such as missing parts, offset, reverse, floating height, side standing, poor solder joints, solder beads, oxidation pollution, foreign objects, scratches, etc.

| 型号 | S3020 | |

|---|---|---|

| Visual System | Imaging | 12MP industrialcamera (25MP optionaD |

| Resolution | 5μm/10μm/15μm | |

| Inspection Speed | 0.3S/FOV | |

| Lighting | RGB LED | |

| Hardware | Power Supply | 200V-230V AC 50/60Hz |

| Power | 2.2KW | |

| Air Pressure | 0.4-0.6MPa | |

| Weight | 1000KG | |

| Equipment Dimensions | 1000mm(L)*1270mm(W)*1630mm(H) | |

| Inspeclion Specilications | Substrate Sizes | 510*480mm |

| Substrate Thickness | 0.4-6mm | |

| PCB Edge Clearance | 3mm | |

| Top and Bottom Board Clearance | 45mm | |

| Transport Height | 900±50mm | |

| Optional Features | Auiliary Functions | Remote centralized review, barcode reading, QCR recongnition |

| Inspection Items | Defects inspection | Missing components, offset, overturn, billboard, tombstoning, poor soldering joint, solder balls, oxidation pollution, foreign material, scracthes, etc. |