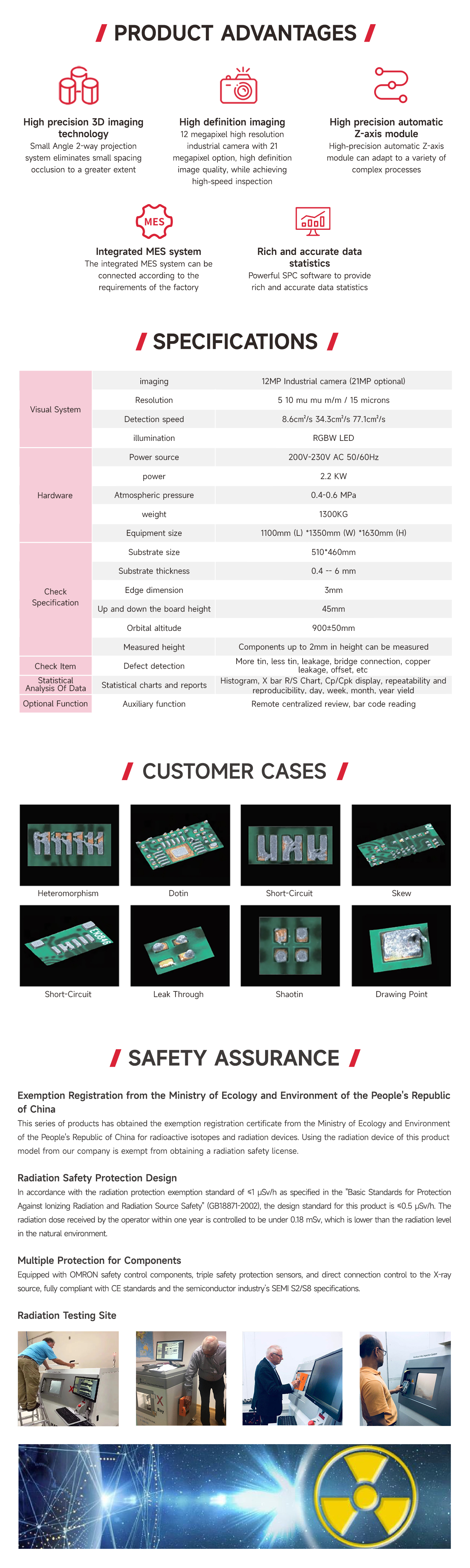

SP3100 is a pre-programmed SMT solder paste printing automatic optical inspection equipment, equipped with multi angle RGBW light source, two sets of small angle projection systems, high-resolution industrial camera with telecentric lens, and high-precision automatic Z-axis module. The equipment scans the solder paste on the surface of the PCB in a 2D+3D manner and generates three-dimensional contour data through phase shift technology. It can measure the height, volume, area, etc. of the solder paste with an accuracy of micrometers and is suitable for complex processes. It can achieve high-precision 3D automatic inspection and inspect defects such as excessive tin, insufficient tin, missing printing, bridging, copper leakage, and offset.

| 型号 | SP3100 | |

|---|---|---|

| Visual system | Imaging | 12MP industrial camera (21MP optional) |

| Resolution | 5μm/10μm/15μm | |

| Inspection speed | 8.6c㎡/s 34.3c㎡/s 77.1c㎡/s | |

| Illumination | RGBW LED | |

| Hardware | Power supply | 200V-230V AC 50/60Hz |

| Power | 2.2KW | |

| Air pressure | 0.4-0.6MPa | |

| Weight | 1300KG | |

| Dimensions | 1100mm(L)*1350mm(W)*1630mm(H) | |

| Inspection specifications | PCB sizes | 510*460mm |

| PCB thickness | 0.4-6mm | |

| PCB edge clearance | 3mm | |

| Top and bottom board clearance | 45mm | |

| Transport Height | 900±50mm | |

| Measuring height | Maxium measurement height up to 2mm | |

| Inspection items | Defects Inspection | Excess solder, insufficient solder, missed print, bridging, missing copper, offset, etc. |

| Data statistical analysis | Statistical graphs and reports | Histogram, X bar R/S Chart, Cp/Cpk Display, Reproducibility and Repeatability, Daily/Weekly/ Monthly/Annual Yield Rate |

| Optional functions | Auxiliary functions | Remote Centralized Review, Barcode Reading |