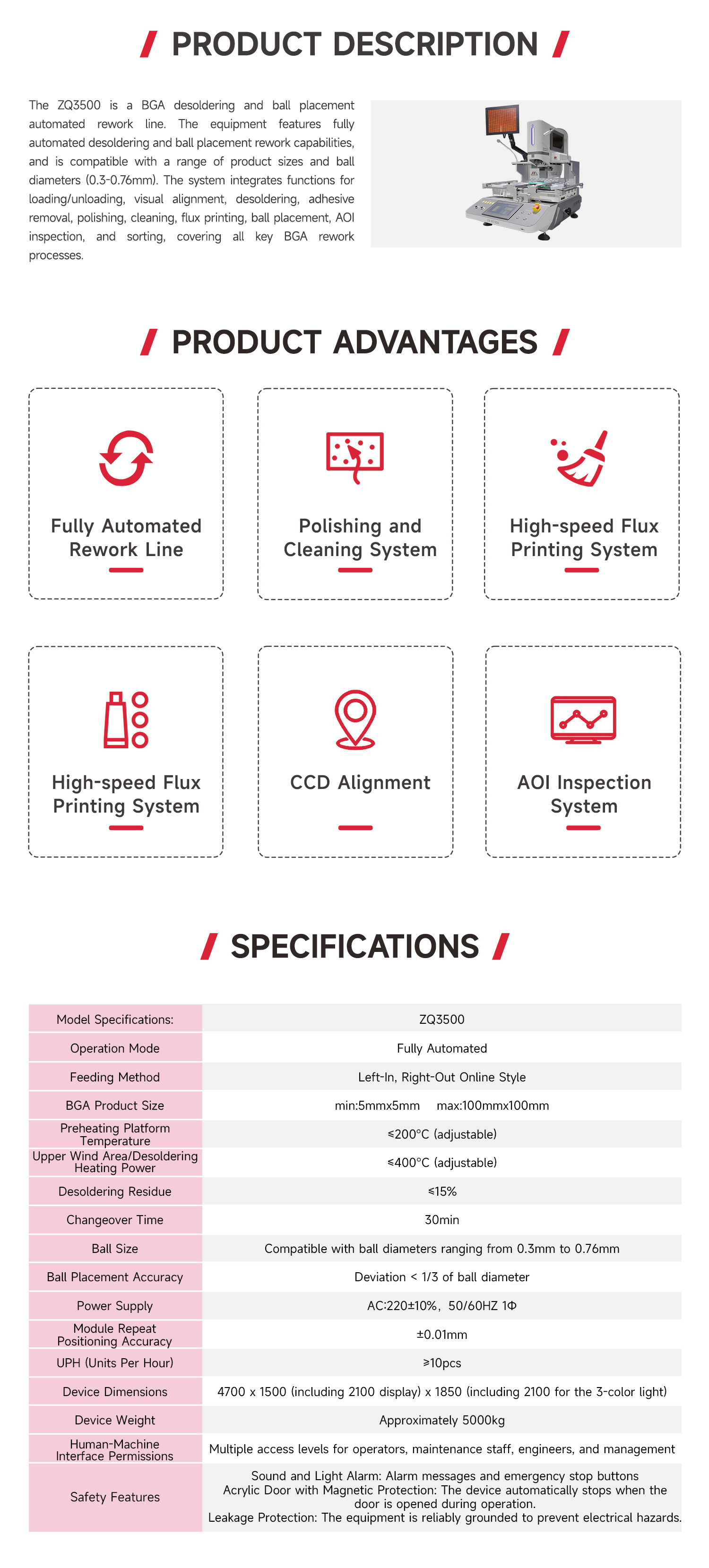

Z03500 is an automatic BGA rework line designed for tin removal and rebaling. The equipment offers full automation capabilities for desoldering and reballing, and it is compatible with a wide range of product sizes and ball diameters (0.3-0.76mm). The entire system includes functions such as loading and unloading, visual alignment, desoldering and adhesive removal, polishing, cleaning, flux printing, reballing, AOl (Automated Optical Inspection) inspection, and sorting, covering all the necessary processes for BGA rework.

| 型号 | ZQ3500 | |

|---|---|---|

| Equipment Specifications | Work Method | Fully automatic |

| Feeding method | Left-in, right-out inline | |

| BGA product dimensions | min:5mmx5mm max:100mmx100mm | |

| Preheating table temperature | ≤200°C (adjustable) | |

| Upper air zone / Desoldering heating equipment quantity | ≤400°C (adjustable) | |

| Tin residue removal | ≤15% | |

| Line change time | 30min | |

| Tin ball size | 0.3mm-0.76mm | |

| Reballing accuracy | The deviation is less than 1/3 of the ball diameter | |

| Power supply | AC:220±10%, 50/60HZ 1Φ | |

| Module repeatability | ±0.01mm | |

| UPH | ≥10pcs | |

| Dimensions | 4700x1500 (including 2100 display path) x1850 (including 2100 tri-color LEDs) | |

| Weight | 5000KG | |

| Human-machine permissions | Four access control modes: operator, maintenance personnel, engineering personnel, and management personnel. | |

| Safety | Audible and visual alarms, alarm information prompts, emergency stop button, front acrylic door with magnetic protection (opening the door during operation will automatically stop the equipment), leakage current protection device, and reliable grounding. |