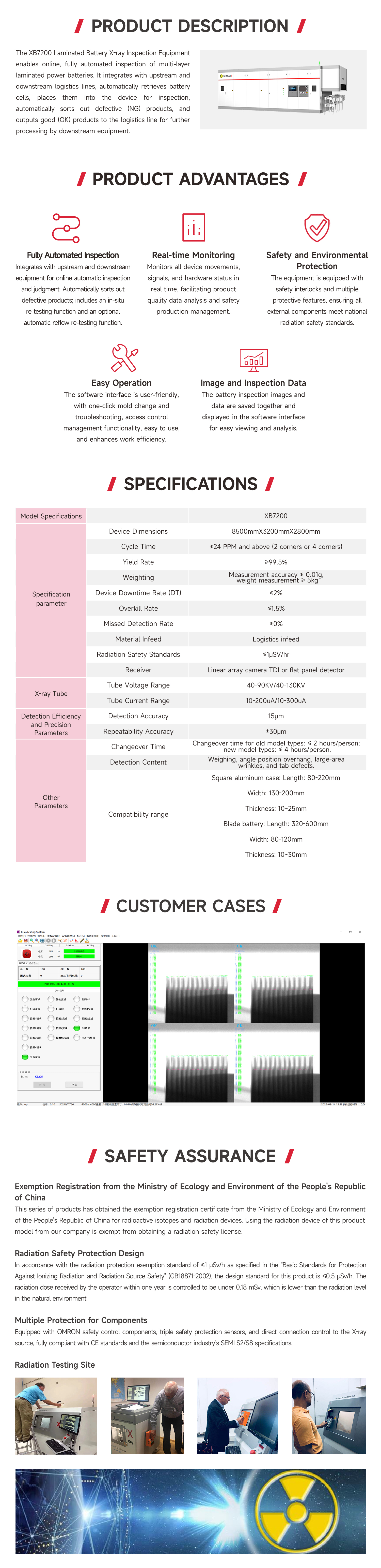

XB7200 stacking battery X-ray inspection equipment enables fully automatic inline inspection of multi-layer stacking lithiumion batteries. It integrates with upstream and downstream logistics lines, allowing for automatic battery picking, placement into the device for inspection, automatic sorting of defective (NG) products, automatic removal of acceptable (OK) products, and output to the logistics line for further processing by downstream equipment.

| 型号 | ||

|---|---|---|

| Equipment Specifications | Dimensions | 8500x3200x2800mm |

| Cycle Time | ≥24 PPM or above (2corners or 4 corners) | |

| Yield Rate | ≥99.5% | |

| Weigh | Measurement accuracy is less than 0.01g and the quantity is more than 5kg | |

| Equipment Failure Rate (DT) | ≤2% | |

| Overkill Rate | ≤1.5% | |

| Missed Kill Rate | ≤0% | |

| Material Feeding Method | Logistic Line Feeding | |

| Radiation Safety Standard | ≤1uSV/hr | |

| Receiver | Linear Camera TDI or Flat Panel Detector | |

| X-Ray Tube | Tube Voltage | 40-90KV/40-130KV |

| Tube Current | 10-200μA/10-300μA | |

| Inspection Efficiency and Accuracy Parameters | Inspection Accuracy | 15μm |

| Repeatability Accuracy | ±30μm | |

| Other Parameters | Changeover Time | For old products: ≤2 hours/person For new products: ≤4 hours/person |

| Inspection Items | Weighing, angle overhanng, large wrinkles, tab crease, etc. | |

| Compatible Range | Square aluminum shell: length: 80-220mm width: 130-200mm thickness: 10-25mm blank battery: length: 320-600mm width:80-120mm thickness: 10-30mm |