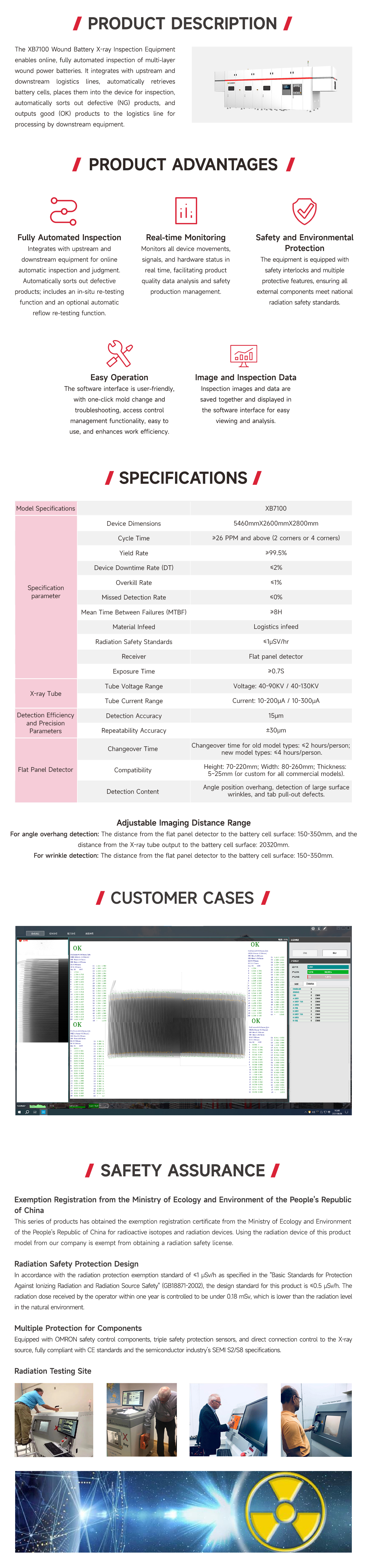

XB7100 winding battery X-ray inspection equipment realizes fully automatic inline inspection of multi-layer winding power batteries, connects with upstream and downstream logistics lines, realizes automatic cell removal, puts into the equipment for inspection, and automatically sorts NG products automatically takes out OK products, outputs the logistics line, and enters the downstream equipment.

| 型号 | ||

|---|---|---|

| Equipment Specifications | Dimensions | 5460x2600x2800mm |

| Cycle Time | ≥26PPM or above (2corners or 4 corners) | |

| Yield Rate | ≥99.5% | |

| Equipment Failure Rate (DT) | ≤2% | |

| Overkill Rate | ≤1% | |

| Missed Kill Rate | ≤0% | |

| Mean Time Between Failures (MTBT) | ≥8H | |

| Material Feeding Method | Logistic Line Feeding | |

| Radiation Safety Standard | ≤1uSV/hr | |

| Receiver | Flat Panel Detector | |

| Exposure Time | ≥0.7S | |

| X-Ray Tube | Tube Voltage | 40-90KV/40-130KV |

| Tube Current | 10-200μA/10-300μA | |

| Inspection Efficiency and Accuracy Parameters | Inspection Accuracy | 15μm |

| Repeatability Accuracy | ±30μm | |

| Other Parameters | Changeover Time | For old products: ≤2h/person For new products: ≤4h/person |

| Compatible Time | Height: 70-220mm; width: 80-260mm; thickness: 5-25mm (or customized for all models on the market) | |

| Inspection Items | Angle overhang, surface wrinkles inspection, extreme needle pulling |