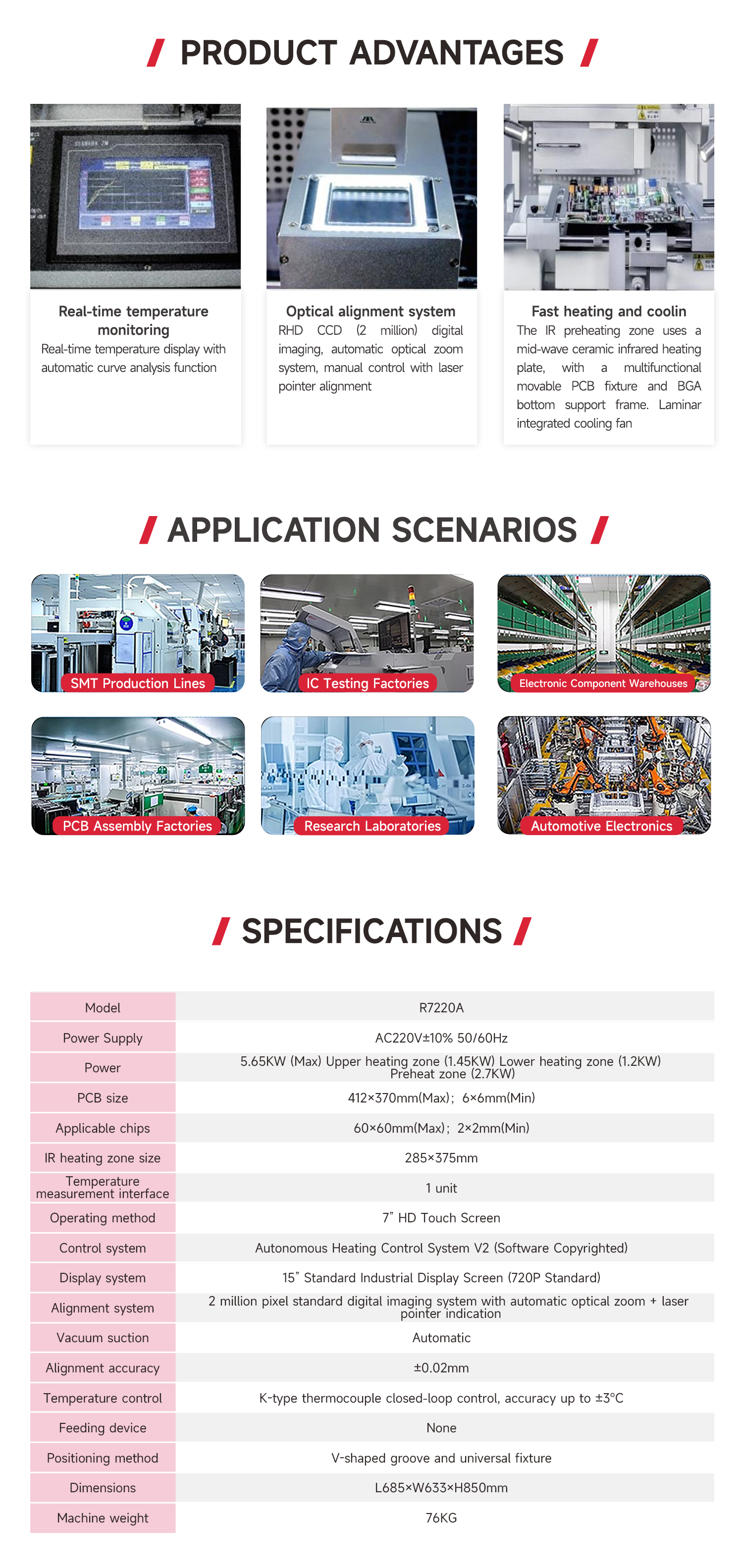

The ZM-R7220A is a versatile optical alignment automatic repair device featuring real-time temperature monitoring, automatic optical zoom, and joystick-controlled head elevation and image scaling. Its high-definition optical alignment system enables precise splitting, magnification, reduction, and fine-tuning. The device also incorporates medium-wave ceramic infrared heating plates, a multifunctional mobile PCB mounting bracket, and a BGA bottom support frame.

| 型号 | ZM-R7220A | |

|---|---|---|

| Equipment Performance Parameters | Power Supply | AC220V±10% 50/60Hz |

| Power | 5.65KW (Max) Top zone (1.45KW) Buttom zone (1.2KW) Preheating zone (2.7KW) | |

| PCB Size | 412x370mm(Max); 6x6mm (Min) | |

| BGA Chip Size | 60×60mm(Max);2x2mm(Min) | |

| IR Temp. Zone Size | 375x285mm | |

| Temp. Sensor | 1 PCS | |

| Operation Method | 7“ HD touch screen | |

| Control System | AutonomousHeating Control System V2 (Software Copyrighted) | |

| Display System | 15“HD industrial display screen | |

| Vacuum Adsorption | Automatic | |

| Alignment System | 2m high-definition digital imaging system, automatic optical zoom + laser red dot indicator | |

| Alignmenr Accuracy | ±0.02mm | |

| Temp. Control | K-type thermocouple closed-loop control with accuracy up to ±1°C | |

| Feeding Device | No | |

| Positioning | V-groove and universal fixture (shaped fixture can be customized) | |

| Dimensions | L685xW633×H850mm | |

| Weight | 76KG |